Resource Precision-engineered Bobcat Aftermarket Parts for Boosted Capability

Resource Precision-engineered Bobcat Aftermarket Parts for Boosted Capability

Blog Article

Taking Full Advantage Of Effectiveness: The Role of Aftermarket Parts in Machinery and Heavy Equipment

In the realm of machinery and heavy equipment, the mission for optimal efficiency is a perpetual quest. One vital facet that frequently goes unnoticed however holds immense potential is the utilization of aftermarket components. These parts, while occasionally overlooked, play a crucial duty in the efficiency and durability of tools. From cost-saving measures to enhancing operational effectiveness, aftermarket components have verified to be crucial in taking full advantage of performance in numerous sectors. As we explore the details of this subject, a much deeper understanding of the benefits and effects of aftermarket parts will undoubtedly clarify their essential duty in the realm of machinery and heavy equipment.

Benefits of Making Use Of Aftermarket Parts

Utilizing aftermarket components in machinery and hefty devices can result in cost financial savings and enhanced functional effectiveness. One of the key advantages of utilizing aftermarket parts is the potential for considerable cost reductions compared to buying original equipment supplier (OEM) parts. Aftermarket parts are frequently a lot more competitively priced, allowing organizations to minimize expenses without endangering on high quality. This cost-effectiveness is especially beneficial for business aiming to enhance their maintenance spending plans without compromising the performance and dependability of their machinery.

Moreover, aftermarket components can provide a more comprehensive range of choices and schedule than OEM parts. By leveraging the advantages of aftermarket components, companies can accomplish affordable upkeep solutions while improving the efficiency and longevity of their machinery and hefty tools.

Cost-Saving Strategies

Provided the economic benefits connected with aftermarket parts, discovering reliable cost-saving techniques ends up being vital for organizations seeking to maximize their operational effectiveness and upkeep spending plans. One vital strategy is to conduct complete study to identify respectable aftermarket components distributors that offer top quality products at competitive costs. By partnering with trustworthy distributors, organizations can safeguard cost-effective services without compromising on the performance or longevity of their machinery and heavy equipment.

Another cost-saving strategy is to implement proactive upkeep techniques that focus on the prompt substitute of parts before they fail. By investing in preventive maintenance and replacing parts with aftermarket components prior to they reach the end of their life span, businesses can stay clear of pricey downtime, emergency situation repairs, and possible damages to various other components of the tools.

Furthermore, leveraging bulk buying arrangements with aftermarket components distributors can bring about substantial expense savings for services with huge fleets of equipment and devices. By negotiating desirable prices terms based on quantity purchases, firms can minimize their overall upkeep costs while ensuring they have a trusted supply of aftermarket parts to support their procedures.

Enhancing Equipment Efficiency

Enhancing tools efficiency requires a critical method that includes maximizing upkeep schedules and utilizing sophisticated technological options. Implementing proactive maintenance routines, consisting of regular examinations, lubrication, and parts replacements, can avoid unforeseen failures and lengthen the life-span of the machinery.

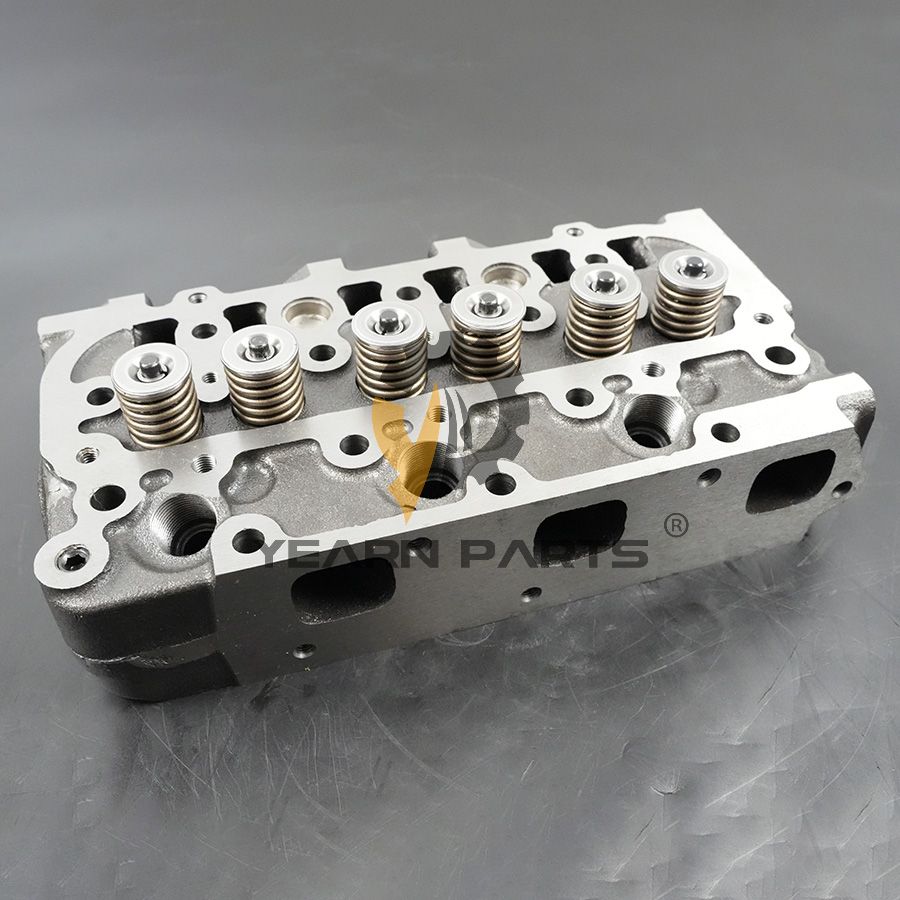

Furthermore, spending in aftermarket components that are particularly developed for enhancing tools efficiency can likewise play a significant duty. By integrating tactical maintenance techniques with cutting-edge technical services and aftermarket parts, businesses can maximize tools performance and optimize their operational efficiency.

Decreasing Downtime

One effective method for minimizing downtime is the use of high-grade aftermarket parts. These parts are created to fulfill or go beyond the performance of original devices supplier (OEM) components, ensuring dependable operation and decreasing the danger of unforeseen malfunctions.

Normal upkeep timetables that consist of the examination and substitute of used parts with aftermarket components can aid protect against tools failings and lengthen the life-span of equipment (Bobcat Aftermarket Parts). By proactively attending to possible problems, services can lessen the regularity and duration of downtime, ultimately making best use of performance and productivity

In addition, having a supply of frequently needed aftermarket parts on hand can expedite fixing procedures and minimize equipment downtime. Quick access to these components allows maintenance teams to promptly resolve problems as they occur, reducing disruptions to procedures and keeping projects on course. Generally, prioritizing making use of aftermarket components can play a vital function in minimizing downtime and maximizing devices performance over time.

Boosting Equipment Lifespan

Expanding the operational longevity of equipment and heavy tools is vital for companies looking for to enhance investments and preserve consistent performance levels. Enhancing the life-span of equipment entails proactive upkeep techniques, prompt repair work, and making use visit this website of top notch aftermarket parts. By applying an extensive maintenance timetable that includes normal like it assessments, lubrication, and component replacements when necessary, services can prevent early wear and break downs that can significantly lower equipment life-span.

Using aftermarket components specifically created for hefty machinery can likewise add to extending devices lifespan. These parts are commonly more affordable than initial tools manufacturer (OEM) parts without jeopardizing on top quality. Aftermarket components are manufactured to meet market criteria and can offer comparable efficiency and longevity to OEM elements.

In addition, drivers and upkeep personnel play an important duty in prolonging devices life-span by following appropriate operating treatments, conducting regular checks, and promptly dealing with any type of concerns that emerge. By focusing on tools longevity with positive upkeep, the demand for early substitutes is reduced, ultimately saving companies time and cash while ensuring functional efficiency.

Verdict

Finally, aftermarket parts play a crucial role in making best use of performance for equipment and heavy equipment. By utilizing these parts, organizations can profit from cost-saving strategies, improved devices performance, decreased downtime, and boosted tools lifespan. Generally, using aftermarket parts provides a useful option for maximizing the effectiveness and performance of machinery and heavy tools operations.

One of the key advantages of using aftermarket components is the capacity for significant expense reductions contrasted to purchasing initial equipment supplier (OEM) parts.Furthermore, aftermarket components can offer a more comprehensive range of alternatives and accessibility than OEM components - Bobcat Aftermarket Parts. These parts are made to satisfy or go beyond the performance of initial devices supplier (OEM) parts, making certain trusted this hyperlink operation and minimizing the risk of unforeseen failures

Report this page